Asset Condition Monitoring & Analysis

Unified approach to asset integrity

Unparalleled visibility

& control

Expert insights

& practical recommendations

Maximized

uptime, safety,

& throughput

MISTRAS provides cutting-edge asset condition monitoring and analysis solutions to help prevent failures, optimize performance, and extend asset lifespan. Our technologies enable early detection of leaks, mechanical wear, fatigue, electrical degradation, and structural weaknesses.

Schedule expert consultation

Monitoring technologies for industrial applications

Ensuring the reliability and efficiency of industrial assets requires proactive condition monitoring and analysis. MISTRAS Group specializes in innovative monitoring solutions that detect early signs of degradation.

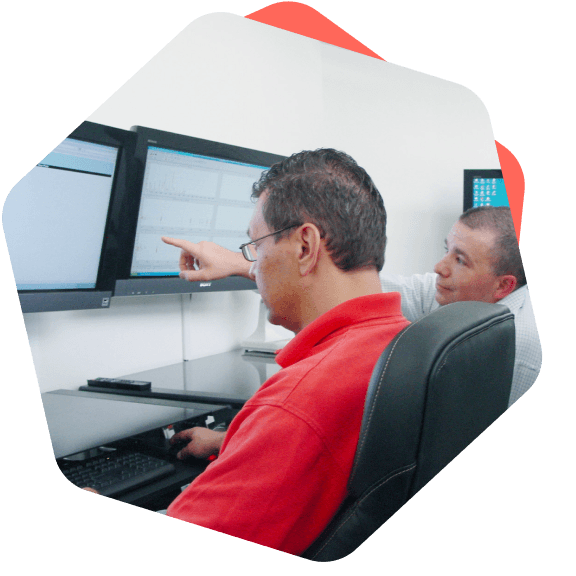

Our data-driven technologies provide real-time insights to mitigate risks, reduce downtime, and maximize asset longevity.

MISTRAS utilizes advanced technologies—like acoustic and ultrasonic leak detection and real-time data analytics—to identify issues such as leaks, fatigue, mechanical wear, and electrical degradation at their earliest stages. This proactive detection minimizes unplanned downtime, reduces safety risks, and prevents catastrophic failures.

Continuous monitoring allows for timely interventions and data-driven maintenance decisions, which help optimize asset efficiency and extend operational lifespans. By tracking degradation and performance trends, organizations maintain optimal asset health and avoid costly replacements.

Get actionable insights and automated reporting that support regulatory compliance, risk mitigation, and maintenance planning. Our solutions improve asset visibility, streamline condition-based strategies, and ensure operations are both safe and efficient.

The right solution for every asset challenge

Explore our asset condition monitoring & analysis solutions below, and contact MISTRAS to enhance your operations.

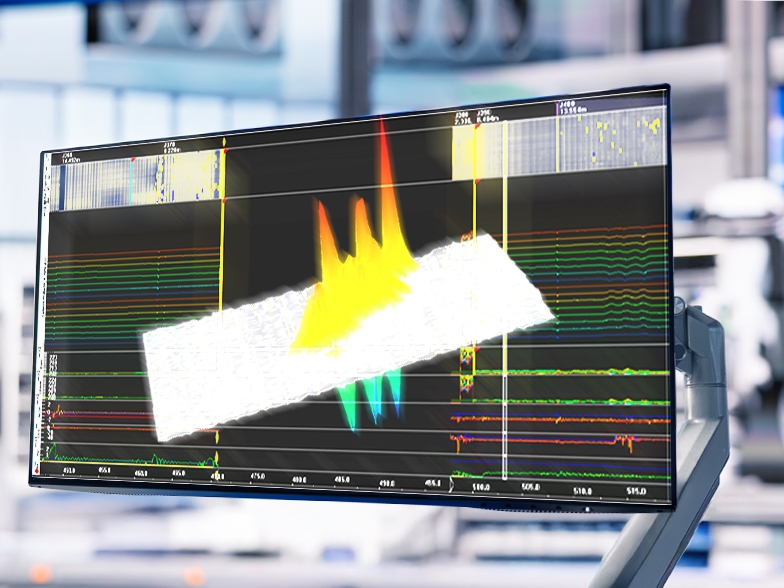

Leak Detection

Undetected leaks in industrial systems can lead to costly inefficiencies, safety hazards, and environmental damage. MISTRAS offers advanced acoustic and ultrasonic leak detection technologies to pinpoint and quantify leaks in boiler tubes, valves, and other critical assets. By detecting leaks early, we help industries improve efficiency and maintain regulatory compliance.

Learn more

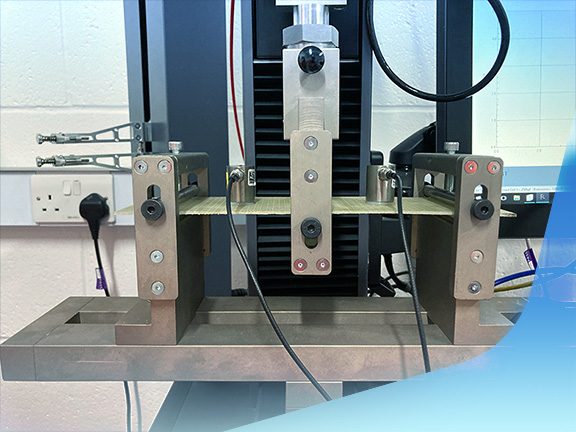

Mechanical Wear, Fatigue & Crack Detection

Industrial components are subject to continuous stress, leading to wear, fatigue, and cracks that can compromise safety and performance. Our condition monitoring solutions provide real-time data on asset health, allowing for early intervention. We specialize in detecting wire breaks, assessing steel fatigue and cracking, and helping to ensure safety and longevity of bridges, wind turbines, and low-speed bearings.

Learn more

Electrical & Thermal Degradation Monitoring

Electrical and thermal failures can lead to catastrophic damage in power systems. MISTRAS offers monitoring solutions for power transformers health and fitness, using thermal imaging, partial discharge detection, and other techniques to identify early signs of degradation. Our solutions help industries prevent failures, optimize maintenance, and extend asset lifespan.

Learn more

Structural Health Monitoring (SHM)

Structural integrity is crucial for the safety and longevity of infrastructure and renewable energy assets. Our SHM solutions use sensors, data analytics, and remote monitoring to detect stress, fatigue, and other structural issues in critical assets like bridges, wind turbines, and other renewable energy structures. This proactive approach minimizes risks and enhances asset performance.

Learn more

Research & Specialist Applications

MISTRAS continuously innovates and develops specialized monitoring applications for unique industry challenges. Our research-driven approach enables us to customize solutions for complex asset monitoring needs, whether in aerospace, defense, oil and gas, or other highly-specialized sectors. By staying at the forefront of technology and partnering with our clients to meet unique needs, we provide cutting-edge solutions tailored to evolving industry demands.

Learn moreExplore our solutions

Through asset performance management (APM) software platforms, advanced engineering services, pipeline integrity solutions, and condition-monitoring technologies and data analysis, MISTRAS provides an unmatched portfolio and data-driven approach to asset optimization.

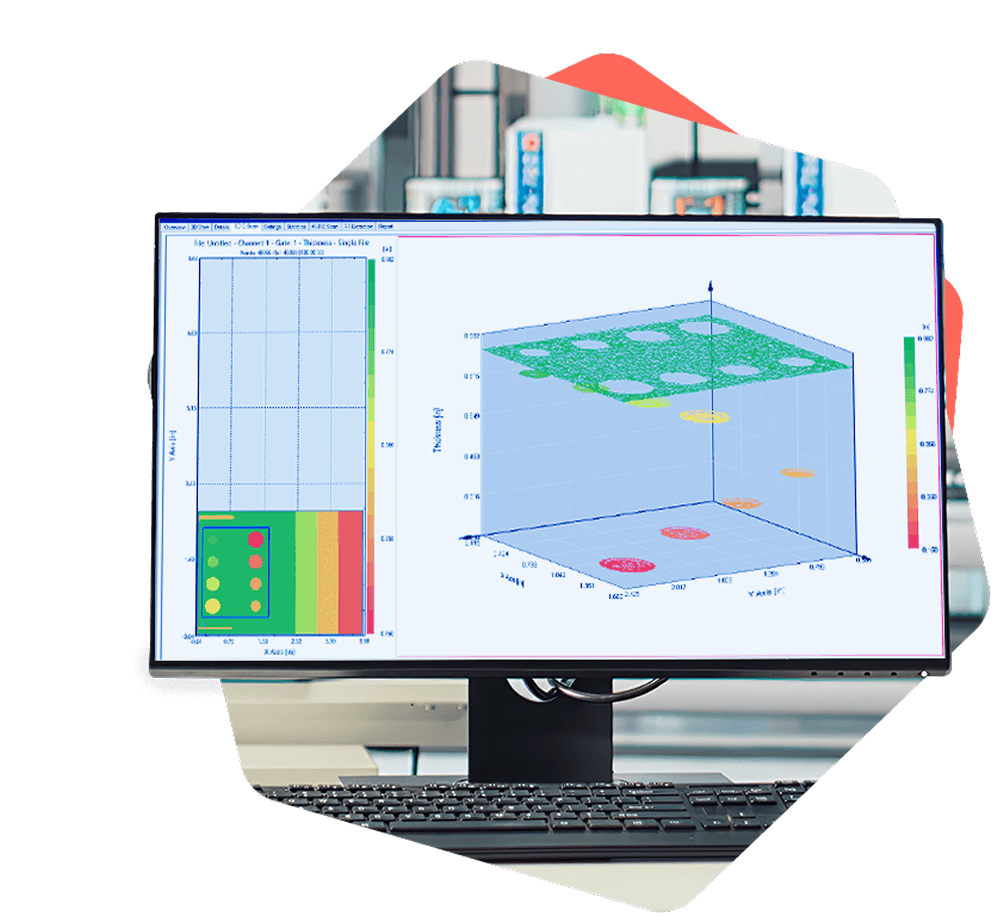

MISTRAS’ proprietary asset integrity software platforms leverage real-time data analytics and streamlined data management workflows to optimize asset reliability, moving you from reactive to proactive maintenance, reducing unplanned downtime and enhancing operational efficiency.

MISTRAS’ engineering experts provide critical analysis and evaluation services to improve asset integrity and performance. From mechanical integrity programs to fitness-for-service (FFS) assessments and risk-based inspection (RBI), our solutions help ensure compliance and extend the life of critical infrastructure.

Enhance the safety and compliance of your pipeline assets. We provide advanced inspection, risk assessment, geospatial, and data management solutions to help identify and mitigate potential failures before they become costly incidents.

MISTRAS’ proprietary asset integrity software platforms leverage real-time data analytics and streamlined data management workflows to optimize asset reliability, moving you from reactive to proactive maintenance, reducing unplanned downtime and enhancing operational efficiency.

Learn moreMISTRAS’ engineering experts provide critical analysis and evaluation services to improve asset integrity and performance. From mechanical integrity programs to fitness-for-service (FFS) assessments and risk-based inspection (RBI), our solutions help ensure compliance and extend the life of critical infrastructure.

Learn moreEnhance the safety and compliance of your pipeline assets. We provide advanced inspection, risk assessment, geospatial, and data management solutions to help identify and mitigate potential failures before they become costly incidents.

Learn moreMISTRAS’ innovative monitoring solutions help detect early signs of degradation, along with specialty research applications. Our data-driven technologies provide real-time insights to mitigate risks, reduce downtime, and maximize asset longevity.

Learn moreAnswer a few simple questions to get recommended solutions tailored to your needs. Select your industry to proceed.

Leverage our solutions & expertise for your asset integrity

Discover how MISTRAS Data Solutions' integrated technologies, platforms, and engineering services can empower your team to achieve "Data-Driven Asset Integrity" and keep your operations "Always On."

Schedule expert consultation