Country Websites

Business Websites

MISTRAS Group’s TriStream MFL™ is a game-changing inline inspection (ILI) technology that measures axial, radial, and circumferential signals for unparalleled detail on metal loss, deformation, and precise pipeline positioning.

MISTRAS Group’s TriStream MFL™ is an advanced, ultra-high-resolution inline inspection (ILI) solution that delivers superior pipeline integrity data.

By capturing multiple magnetic flux leakage (MFL) vectors, the TriStream MFL offers an in-depth look at corrosion, dents, gouges, and other threats that can jeopardize pipeline health. This multi-vector approach, combined with caliper and Inertial Measurement Unit (IMU) technology, helps operators gain a comprehensive overview of pipeline anomalies and locate them accurately along your network.

TriStream MFL’s multi-vector data, small-diameter bend capacity, and speed control features are all designed to improve operational productivity. By reducing unplanned downtime and the need for repeated runs, TriStream MFL delivers:

Traditional MFL pigging tools often measure one or two signal vectors, potentially leaving gaps in inspection data. The TriStream MFL’s triaxial sensor capabilities helps overcome these limitations by measuring three separate magnetic signals simultaneously—axial, radial, and circumferential. This configuration provides detection of:

By offering a truer representation of the pipeline wall’s condition, operators can make confident decisions that mitigate risk and ensure compliance with strict regulatory requirements.

The TriStream MFL pigging tool can inspect lines from 4”-36” in diameter, making it an ideal choice for both small gathering lines and large transmission pipelines.

MISTRAS’ 4” TriStream MFL services is unique in its ability to navigate pipelines with multiple 1.5D bends, serving as a combination MFL, caliper, and inertial measurement unit (IMU) tool that provides metal loss, deformation, and GPS positioning assessments for lines that were previously considered unpiggable.

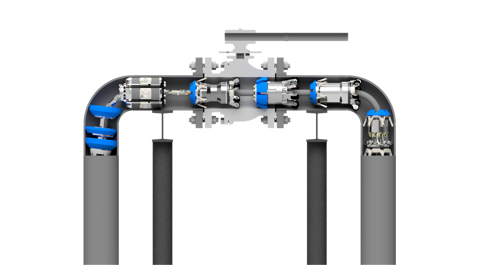

To obtain good data quality during a pipeline inspection, the speed of the tool must be controlled. The TriStream MFL’s speed-control technology automatically opens to let more gas bypass through the tool whenever the tool starts to run too fast, and closes to reduce the amount of gas bypassing through the tool when the tool runs too slow. This allows natural gas pipeline operators to perform inline inspections without having to slow down their pipeline or manipulate their operations, allowing you to maximize pipeline throughput without sacrificing data quality.

Following inspections, MISTRAS Group provides a customized data interpretation package to help operators make timely, informed decisions. This report can include:

With this information in hand, integrity engineers can develop targeted maintenance plans, schedule dig programs efficiently, and align long-term pipeline management strategies with their operational objectives.