Country Websites

Business Websites

MISTRAS’ Centers of Excellence (COEs) are part of our worldwide resource, knowledge, and support network. Our COE experts integrate multiple MISTRAS asset protection specialties to offer technical support for specific industries, assets, and solutions.

Materials "talk" when they are in trouble. Through AE testing, MISTRAS "listens" to the sounds of cracks growing, fibers breaking, and many other modes of active damage in stressed materials. MISTRAS has been an industry pioneer in AE inspection technology and applications for decades.

MISTRAS provides component protection throughout our aerospace partners’ supply chains. We can perform inspections and testing on individual components, or centralize multiple milestones throughout the production cycles of commercial & defense aircraft in a purpose-built facility.

MISTRAS’ comprehensive API turnaround planning, inspection, and maintenance programs are backed by decades of expertise in refinery turnaround execution and management. We develop API turnaround programs designed to address maximize safety practices, minimize environmental hazards, and reduce turnaround costs and downtime.

A sound Asset Integrity Management Services (AIMS) program incorporates various aspects of equipment design, maintenance, inspection programs, and operational management in order to ensure safety and efficiency and to maximize an asset’s financial return. In short, MISTRAS helps our clients realize longer run time, reduced downtime, and enhanced mechanical integrity.

MISTRAS’ Automated Ultrasonic (AUT) inspection services are advanced, accurate, and effective techniques to monitor discontinuities over successive inspection intervals, calculate growth rates of discontinuities, and plan repair or replacement activities.

MISTRAS’ diving services provide industry-leading inspection and maintenance solutions for assets in marine and subsea environments, including bridges, harbors, dams & reservoirs, offshore platforms, underwater pipelines, and highly-contaminated areas such as nuclear fuel tanks.

MISTRAS protects personnel working in at-height locations by providing solutions for the design, installation, and certification of fall protection equipment and procedures.

MISTRAS provides inspection & engineering services for newly-constructed and existing coal-fired, natural gas, and many other fossil plants. MISTRAS' fossil plant services use non-destructive examination (NDE) technology to identify defects in your facility, promoting facility production and preventing costly unplanned shutdowns.

In the hands of an experienced technician, Guided Wave UT can locate and characterize defects internally and externally and will pick up cracking in many cases. Guided Wave UT is used to rapidly inspect pipelines, piping systems, and other assets with minimal insulation removal.

MISTRAS offers inspection, maintenance, monitoring, and access solutions to ensure essential infrastructure assets are free from structural damage. Specializing in bridge structural health monitoring (SHM), we also offer solutions for amusement parks, commercial buildings, ports, dams, roads, and rails.

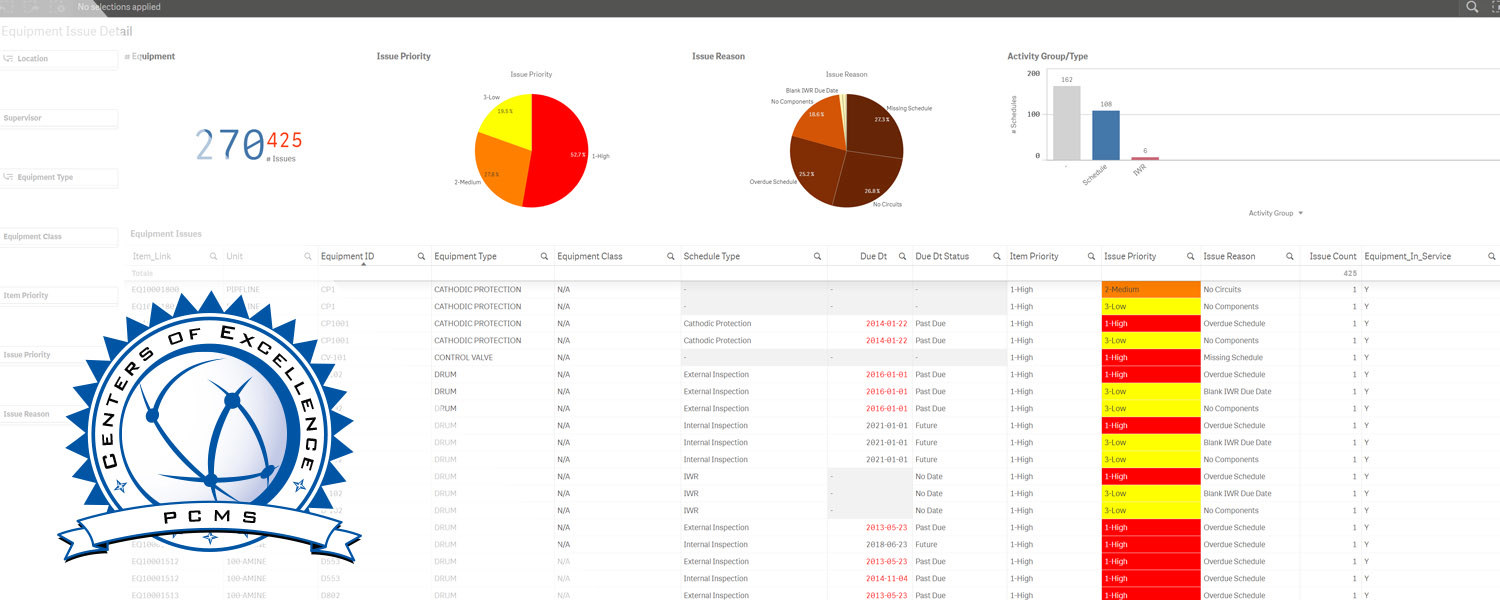

MISTRAS Group’s Plant Condition Management Software, PCMS®, is the industry’s most experienced inspection database management system (IDMS), specializing in asset integrity, corrosion, and inspection data management. The collection of modules embedded in PCMS create a web of interconnected compatibility, eliminating the need to manage multiple applications to perform total asset integrity analysis.

MISTRAS' integrated inspection & maintenance teams keep onsite personnel to a minimum by not only detecting damages, but performing light mechanical services to repair assets and return them to service as quickly as possible.

MISTRAS has been providing support for nuclear construction, maintenance, refueling outages, and major component replacement projects for decades. We’ve provided these solutions for various nuclear reactors, including pressured water reactors (PWR), boiling water reactors (BWR), and Canada deuterium uranium (CANDU).

MISTRAS provides a combination of high-quality inspection, maintenance, and mechanical services, paired with elite access capabilities, to service every aspect of your offshore platform.

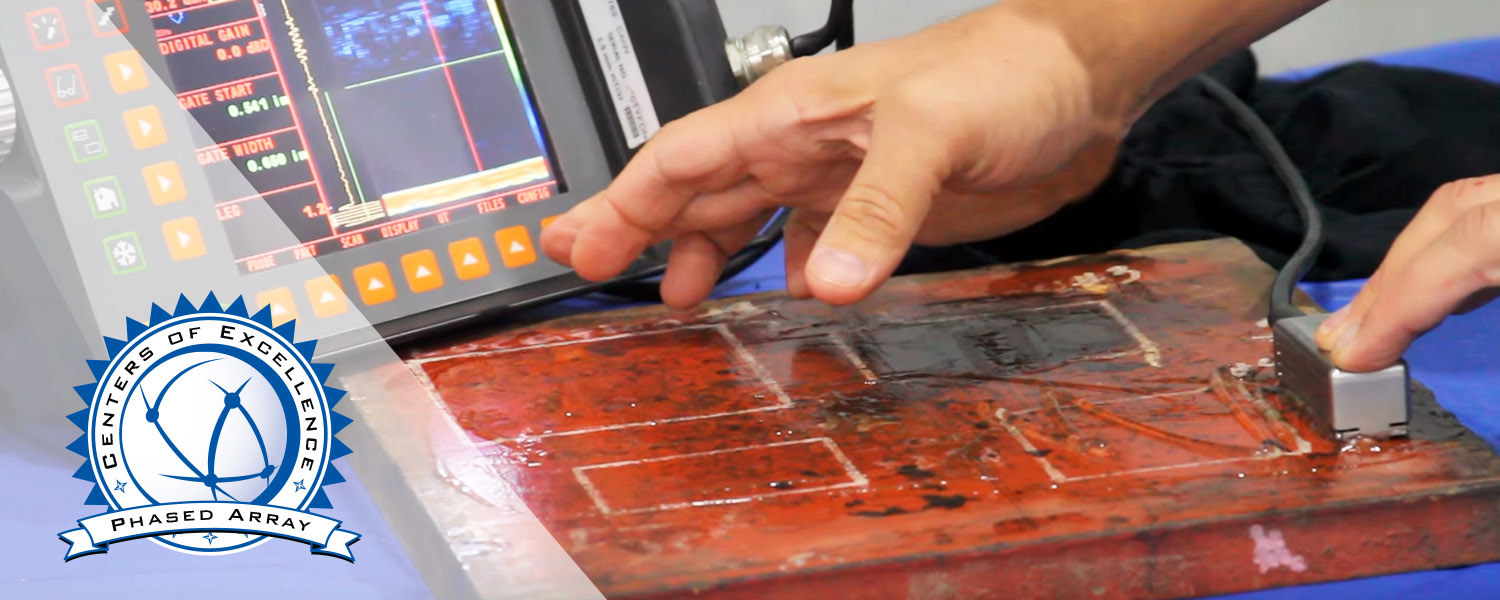

Phased Array (PAUT) inspection is capable of inspecting complex geometries, and accurately and quickly detecting, locating, and sizing defects on a variety of equipment, including welds, pressure vessels, piping, tubing, turbine blades, landing gear cylinders, castings, and many others.

Serving as your OneSource pipeline protection provider, MISTRAS keeps both your new construction and mature pipeline networks streaming smoothly with a full range inspection, engineering, monitoring, and pipeline data management solutions.

MISTRAS has an extensive range of non-destructive examination (NDE) inspection and monitoring solutions to ensure that assets in the combined cycle, fossil, nuclear, and wind energy sectors remain operating safely and efficiently.

MISTRAS provides vibration testing, traditional and advanced non-destructive testing (NDT/ANDT), and engineering consultations for the implementation and execution of comprehensive predictive maintenance (PdM) programs.

MISTRAS has extensive hands-on experience in the design, installation, troubleshooting, problem-solving and inspection of all types of refractory lining systems, including fluid bed combustors, flexi-cokers, fluid cokers, cat crackers, sulfur recovery units, rotary kilns, furnaces, roasters, autoclaves, and boilers.

For assets that are out-of-reach of traditional access points and when scaffolding is not an option, MISTRAS provides rope access services to safely complete inspection, maintenance, and repair services. Our teams work on a wide range of at-height assets across the world.

MISTRAS’ inspection and monitoring specialties for transformers and associated Transmission & Distribution (T&D) assets help plants avoid unplanned outages and keep the lights on for homes and businesses.

MISTRAS supports our clients with high-quality storage tank inspection, engineering, maintenance, access, and data management expertise, as preventing corrosion, cracking, and leaking in refinery storage tanks is crucial for plant productivity, safety, and compliance.

Our ISO 17020-accredited transportation inspection services are backed by decades of fire apparatus and aerial lift device inspection experience.

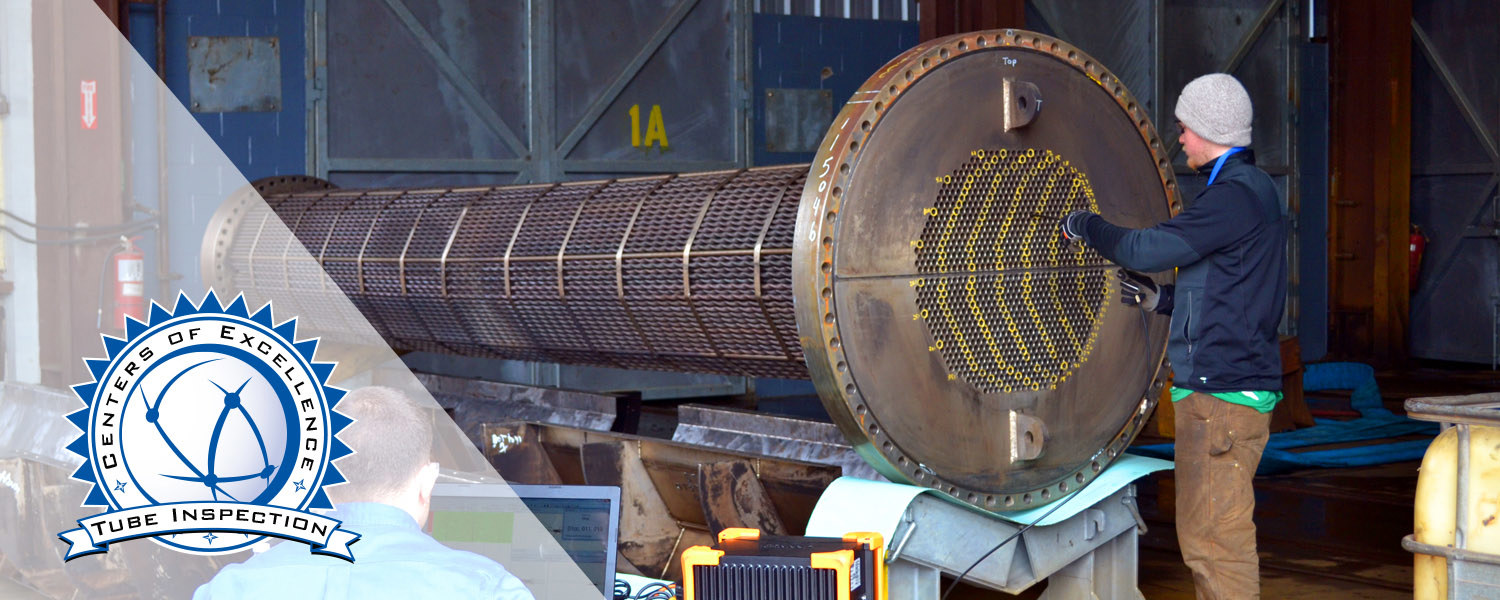

MISTRAS provides comprehensive inspection programs consisting of multiple tube inspection techniques, used to determine the integrity of heat exchanger tube bundles. Our extensive experience in heat exchanger inspection provides the assurance that components are properly evaluated to detect damage or defects, thereby ensuring that tube bundles are safe to remain in operation.

Whether they are in at-height or subsea locations MISTRAS offers unmanned inspection services for the assets and structures that can be hazardous for manned access.

MISTRAS’ blade and turbine services enhance wind projects by maximizing safety and uptime and ensuring the components' peak operating condition. Coupled with Sensoria™, the 24/7/365 wind blade monitor, our teams deliver inspection, maintenance, and monitoring capabilities that help maximize uptime and energy-generating capacity.